Screen-Printing Conductive Ink:

Advancing ThinFilm Antenna Technology

Screen-printing with conductive ink has become a go-to method in the thin film industry—especially for those looking to combine electronics with fabrics. Known for its scalability, speed, and cost-effectiveness, this technique enables high resolution printing while maintaining consistent electrical performance. The thin film substrates tend to be thermoplastic urethanes, extremely thin PET/PEN and Polyimide or even a laminated combination of these micro thin layers.

Leverage my design experience with TFAA’s ThinFilm Flexible Antenna Arrays from my previous clients like Lockheed-Martin, Magnavox, Teledyne Systems, BAE Systems.

So how does it work? Conductive ink is pressed through a mesh screen onto a base fabric, forming patterns that are not just visible, but functional. The final quality of the print depends on several key factors: screen mesh size, the number of print passes, printing speed, ink viscosity, and how the printed material is cured. When optimized, these elements work together to deliver precise, uniform, and highly conductive results.

One major advancement in this space has been the use of highly conductive inks like silver-based inks on fabrics such as polyester, cotton, or nylon. These fabrics serve as flexible, conductive platforms, allowing for the creation of “smart” textiles.

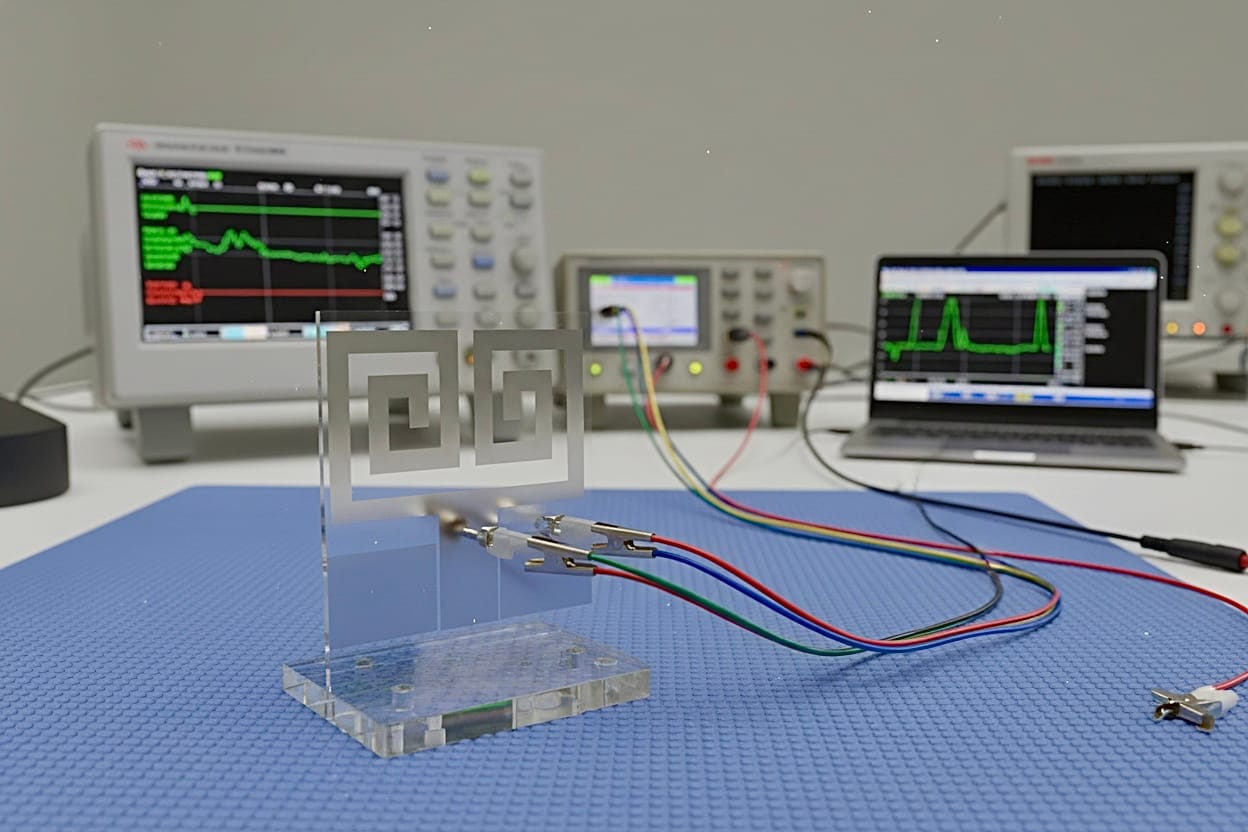

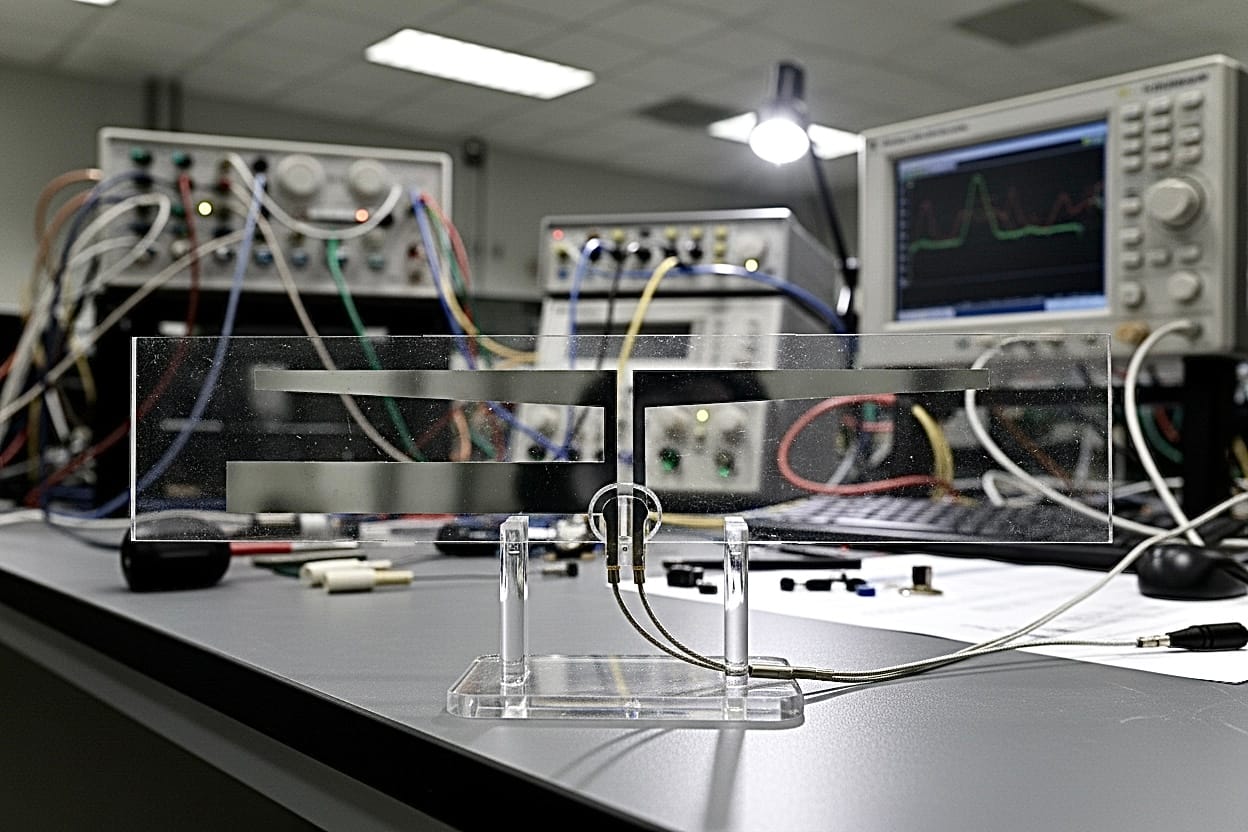

The screen-printing process builds up a thick conductive layer that can be shaped and integrated into various antenna designs. But integrating antennas into everyday fabrics comes with its challenges particularly when it comes to feeding the signal into the antenna. Traditional connectors like the SMA (SubMiniature) offer excellent signal performance but are often bulky and impractical for wearable applications.To address this, researchers have developed simplified patch antennas designed specifically for flexibility and comfort. Using screen-printed silver ink on polyester, they’ve created conductive textiles that maintain strong electrical performance while withstanding stretching and bending—perfect for wearable tech.

These printed antennas have been optimized for two key frequencies: 2.44 GHz and 868 MHz. These frequencies are commonly used in technologies like Bluetooth Low Energy (BLE) and LoRaWAN, both of which are essential for modern applications in long-range tracking, IoT communication, and wireless sensor networks. By merging textile design with advanced printing techniques, screen-printing conductive ink is paving the way for the next generation of smart clothing—where your shirt might not just make a fashion statement, but also help track your fitness or connect you to a network of endless possibilities.