Smart textiles—fabrics that can sense and respond to the environment—are an exciting area of research, especially in healthcare. One key use is in wearable sensors that track health in real time. These sensors can help monitor diseases and improve patient care. Among the different types of wearable sensors, those made with textiles are especially promising. They offer benefits like comfort, flexibility, and being noninvasive (they don’t go inside the body). Let’s take a close look at how these textile-based sensors are designed, built, and used.

Printing Calibrated Sensors

Setting Yourself Up for Success

Successful repetition for extreme tolerance fine calibration medical sensors begins long before the printing process.

This is a great example of how we combine both functional and visual reference points directly within the printed sensor area. During production, we can quickly decide whether to keep printing, pause to make adjustments, or move on to the next layer — all in real time.

Each batch includes four corner metrology markers (A, B, C, and D), die-cut along with the eight printed sensors. These markers are kept as historical samples for strict quality control. They help us track precision over time and set accurate centerline tolerance targets for future print runs.

Real-world uses—like tracking heart rate, movement, or signs of illness—are explored. This post includes findings from studies on how people use and respond to these technologies. Finally, it looks at challenges like making the sensors durable, washable, and suitable for mass production. My goal is to help you develop and improve these smart textiles and bring them into everyday healthcare use.

A Different Perspective in Complex Multi-Layer ThinFilm Sensor Manufacturing

Bring your 2D Drawings to Higher Levels of Understanding

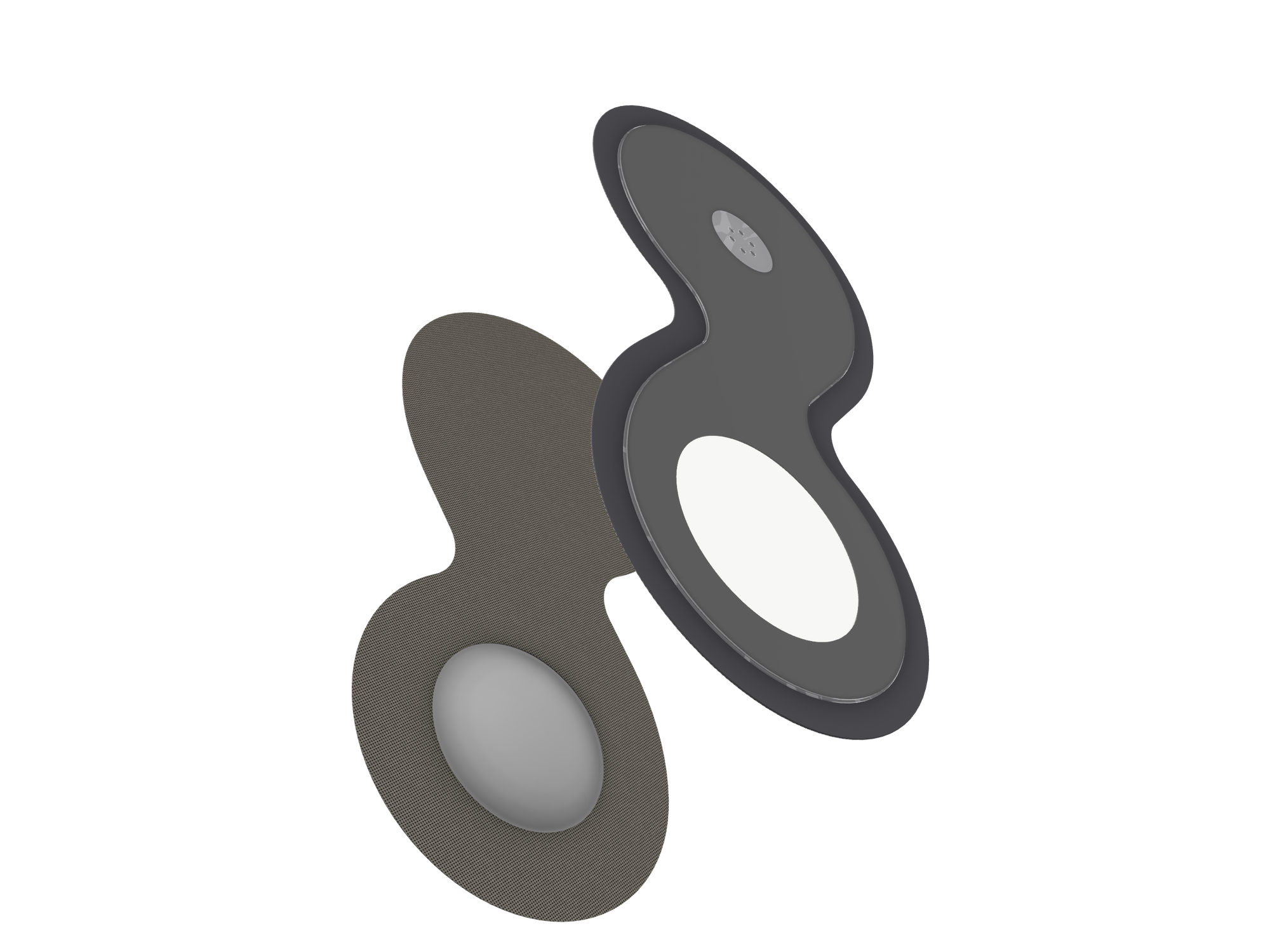

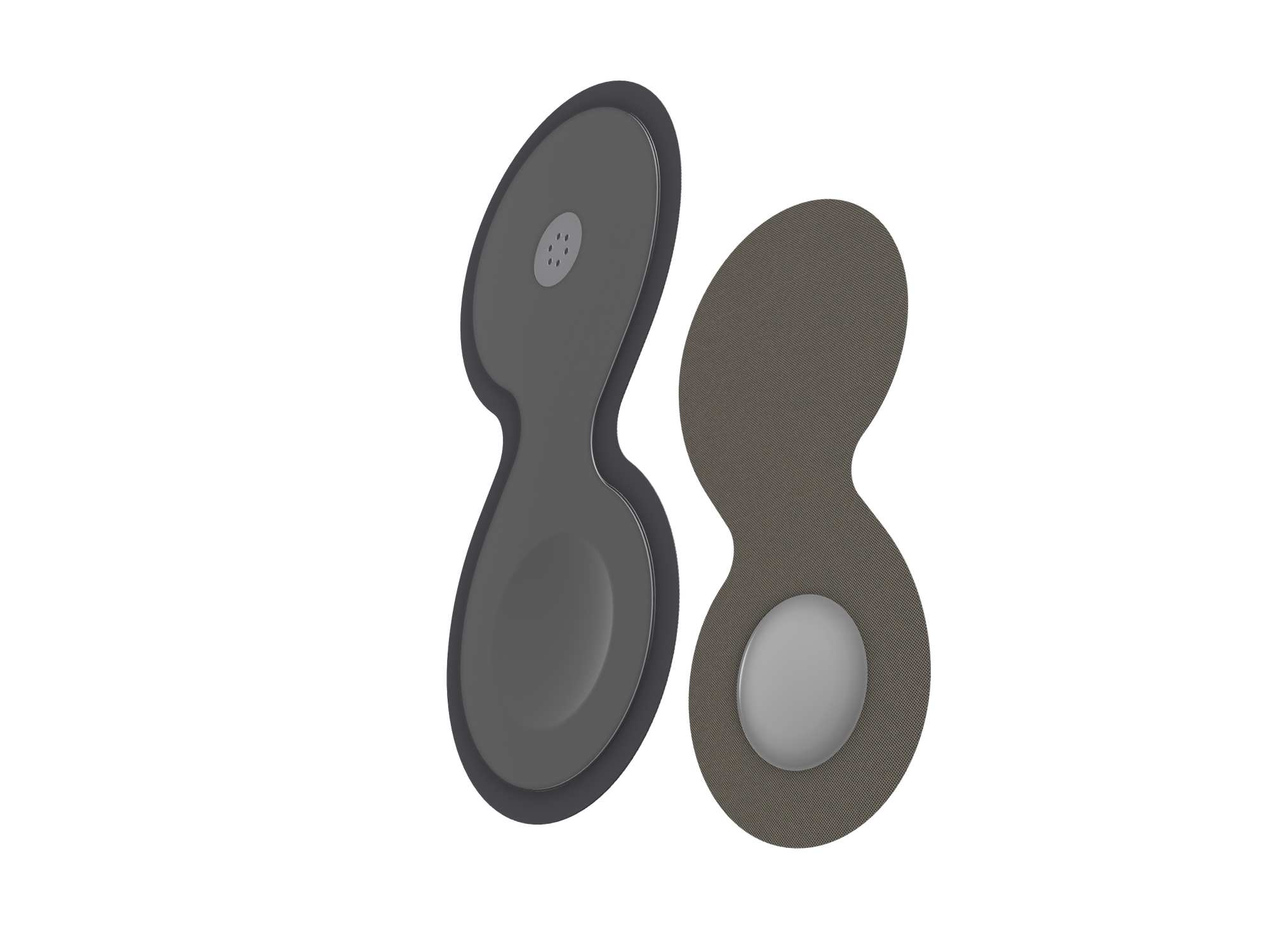

Below are examples of extremely flexible sensors that utilize a HydroFormed dome to create suction that draws interstitial fluid From the patients skin through surface modified micro-fluidic channels into separate internal reaction chambers.

These 3D renderings can be extremely useful for assembly technicians and non-technical personnel in order to better comprehend the design by a different visual perspective. The native output resolution is designed specifically for photographic enlargement suitable for large format framing to decorate your facility.

Learn more about this unusual offering from ThinFilm Design Consultants.